The Solar and Lithium Conversion, Our Most Complex Upgrade

This post is for the folks who might be interested in a few of the technical aspects of our solar and lithium installation. As mentioned in our most recent update, this is getting into the weeds and for most this will be far too long and very boring, so you may want to skip it:

Kenrick and his metal fabrication team (about 5 other guys) from Spice Island Marine designed, constructed, and installed the new solar arch. Kenrick and his team also installed our solar panels. Aaron Downey, owner of Clarity Marine Services, designed, reconfigured, and installed our lithium and electrical upgrades, integrating it all with the new solar installation and our existing solar array.

In the world of boating, having upgrades made can be complicated. Limitations of space often require significant reconfiguration. Just as space is a limitation, money and time are also considerations. Major marine upgrades often require numerous craftsmen and technicians for the different skills and knowledge required to complete an upgrade safely and efficiently. Coordinating their work is often the most difficult part of a large boat project. Our solar and lithium conversion was the most complicated and technical upgrade made on Ocean Song to date, and probably the most technical and complicated we will ever make. It was over a year in the planning, months in the tweaking, and weeks of actual installation. It was pretty much all consuming from mid-September until late October. We pushed hard to have it completed for Lynn and Bryan’s visit and we made it by less than a week. During their visit we were still learning and adjusting to the new system.

To convert from AGM (Absorbed Gas Mat) batteries to a type of lithium (LifePo4 batteries, which are a different chemistry than traditional lithium batteries) supplied primarily by solar, we had to make several major modifications. Although we had a small solar array on the coach roof, totaling 360 watts, we needed a much larger solar array. We calculated, with Aaron’s help, that we needed about 1,600 watts of solar in total.

Solar panels also give sun protection to our dinghy.

New solar array viewed from the cabin top of Ocean Song.

Therefore, we decided to have a solar arch custom fabricated. Kenrick at Spice Island Marine came recommended by several people as one of the best, if not the best, metal fabricator in Grenada. Kenrick had done an arch for S/V Dragonfly, another Lagoon 42, that we really liked. Dragonfly’s owners, Guy and Carole Bazzani, have given us many good ideas and recommendations. Truth be told, we’ve just copied many of the things Guy and Carole have done! The solar arch would allow us to add 1,700 additional watts of bifacial solar, giving us slightly more than 2,000 watts total. Bifacial panels absorb sunlight from the top and bottom. Aaron said the new array alone will be able to supply the new batteries. The old array now provides a nice extra margin.

Old AGM batteries.

Our old AGMs were on their last legs, and we were charging them twice each day by running our generator for 3 to 4 hours each time. Our total usable battery capacity was down to roughly 150-amp hours (1,800 watt-hours). During the day we were basically running our refrigeration, and a few other essentials. The new batteries (4 KiloVault HLX 3600s – 3,600-watt hours/300-amp hours) have given us 1,020 usable amp-hours (12,240 watt-hours). Roughly seven times more available power has been life changing onboard! In practice, it is even more capacity than that, because with our new solar array we can charge the batteries at a higher rate than the discharge on most days. Our AGMs could only be discharged to about 60% state of charge (SOC), a 40% discharge. We tried not to go below 70% SOC due to battery age and the time it took to recharge. The KiloVaults can theoretically discharge to 5% SOC without damage, a 95% discharge. We have set our discharge limit at 75%. Additionally, the KiloVaults charge much more quickly than the AGMs. Unless we go more than 3 days without any normal sunlight, we should not discharge 75% of our capacity. As Guy told us: “It’s like being on shore power all the time.”

2 of the 4 new batteries.

The 4 new batteries are almost twice the size of our 4 old AGMs but weigh 40% less. Because the footprint is much larger, Aaron had to do a significant reconfiguration to fit the new batteries into the available space. It also required many basic electrical components to be removed and/or replaced in our starboard engine compartment where many of our electrical components are housed. Many of the other major electrical components are in a closet in our starboard owners’ cabin.

Rolls of upgraded wiring were pulled from the engine compartment to the central electrical panel.

Batteries and cables to be installed.

All the new “power” meant we needed larger power cables, larger bus bars, larger switches, more and larger breakers, basically higher electrical-handling capabilities in most areas. These upgrades, from the batteries to the various switches and distribution panels, were necessary due to the greater amount of power that will be going through the system. Also, our solar array will be capable of providing far more electricity on sunny days than the batteries can safely absorb. There must be a way to regulate the amount of power flowing from the solar panels to the batteries. That meant installing charge controllers. Charge controllers are battery chargers that can regulate the output from the solar panels. We went with Victron 150/70 controllers, slightly over spec ’ed. It’s complicated, but the controllers can restrict current flow to the batteries when needed and increase current flow under certain conditions. The controllers can manipulate the amps and voltage individually to achieve the best wattage (amps x voltage = watts) for any given output from the solar panels. The controllers make charging the batteries safer, faster, and more efficient.

Closet full of controls.

We also had to install new battery chargers for the times we charge the batteries using our engines or generator. The new batteries can be charged at much higher rates than the old batteries. Therefore, our alternators simply would not be able to keep up and would burn out. The new battery chargers will allow us to charge using the engines and generator without burning up our alternators. The alternator charges will go to the new battery chargers, then to the batteries. We could have replaced our alternators with high output “smart” (regulating) alternators, but Aaron advised that it would be a huge expense and the new battery chargers can perform the same task at a much more reasonable price. As a bonus, the chargers generally last longer and are often more reliable.

Upgraded 3000Watt inverter.

Because we have much more power available, we upgraded our inverter/charger. The inverter converts DC power into AC power and works as a battery charger as well (among many other things it does). We had a good inverter (*1), but now we have a Victron MultiPlus 3000-watt inverter. It’s much smarter than our old inverter and can handle more power and do it much more efficiently, giving us many more options on how to use our available power. It will allow us to run our water maker and even air conditioning off our battery bank. We will not have enough power to run air conditioning all the time, but on sweltering days we will be able to run at least one of our three units for several hours. We also installed “soft starts” on our air conditioners. Soft starts help the air cons start up using less electricity. They will eliminate the surge that normally occurs when the compressors come on.

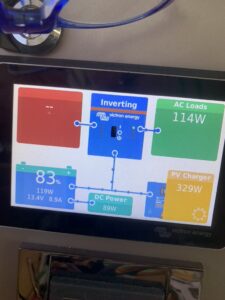

Monitoring panel.

Charge controller

Cerbo computer monitor for (brain) the whole system.

Finally, to keep up with all this and manage our power, we needed help. We installed a Victron Cerbo GX and Victron GX Touch-50 monitoring system. The Cerbo GX is a computer that helps monitor literally all our power needs, consumption, charging, and outputs. We can monitor every .01-amp hour, watt-hour, volt, watt, etc. moving through our electrical system visually in real time 24/7. The system will alarm and shut down if anything is out of spec. It can also reboot itself and start back up on its own. It records everything and even allows us to look at graphic displays of our real-time or historical power management. Even cooler, virtually every major component of our system has built-in Bluetooth. We will be able to monitor our batteries individually, or as a group. We can separately monitor our three start batteries, (2 engines, 1 generator) which are not lithium. The charge controllers have their own Bluetooth monitoring capabilities as well. When the Wi-Fi is on, we can monitor the boat from anywhere in the world if we have a good connection. The Cerbo GX will display the same information on our phones or iPad that we would have available if onboard looking at the GX Touch-50 display. The Bluetooth functions will allow us to change settings if needed to get the most efficiency out of our system. Aaron is also “in network” which allows him to check on things and adjust settings remotely if needed as we go forward.

Installed batteries in the starboard engine bay.

Added busbar and reconfigured control panel in engine bay.

Another of several new busbars.

New charge controller and battery charger installed in starboard engine compartment. Another installed in port engine compartment (not pictured)

Aaron giving us our training for the system.

We have enjoyed working with Aaron. Aaron is an electrical engineer and electrician. As we planned our system, Aaron gave us options and recommendations. He quickly passed one of my litmus tests for honesty – he didn’t steer us to the most expensive alternatives. We told him we didn’t have money to waste, but we didn’t want to cut any corners. Aaron would explain the merits of each option and then tell us what he thought would work best for us. One example was the recommendation of the Victron Multi-Plus 3000-watt inverter. We initially thought a 5000-watt inverter was what we wanted. Aaron could fit the bigger inverter and charge us a lot more money, but he felt strongly that the less-expensive inverter would be more than adequate for our needs. So far, he has been correct. The same for fitting high output smart alternators on our engines. Doable, and more money for Aaron but he said we could get the same practical functionality from much less expensive Victron battery chargers. Aaron also repurposed many of our existing electrical components instead of purchasing new components. He also went beyond normal specs on components that carry the heaviest loads. It was obvious Aaron knew his business and had done many electrical upgrades. He spent many hours planning and diagramming before installation. We highly recommend Aaron Downey of Clarity Marine Services in Grenada.

We already have a good feel for our power consumption and power management after only one month. On an “average Caribbean day” we can replace 25% to 35% of our total battery capacity by solar. Remember all the while we are using electricity, as much as 200 – 400 watts continuously. On a very bright, sunny day with no clouds we can exceed 40% replacement. By 10:30 most mornings we are putting in (net positive) 200 – 500 watts. By 11:30 it’s up to 400 – 800 watts and from noon until 2:30 anywhere from 1000 to 1,700 watts. We usually have good input until about 3:30. By then the angle of the sun cuts down on our solar panel efficiency and we’re back around 200 – 400 watts and by 4:30 we are no longer having a net power gain; we’re about even and soon we’re taking 200 -300 watts out of our batteries. In the Caribbean there are basically 12 hours of light and 12 hours of darkness each day. It’s amazing how much electricity the solar panels produce in just 6 hours or so of full, direct sunlight. The old formula used to be 2 watts of solar for 1 amp hour of battery capacity. For us that would mean 2,400 watts of solar because we have slightly over 1,200-amp hours of battery capacity. However, the bifacial panels are more efficient, and we can cheat on the old 2 to 1 ratio (*2). To our surprise, even on cloudy, rainy days we do produce some energy by solar, only 200 watts or so (not enough for a positive input) but power nonetheless and it reduces our net battery discharge!

With our old batteries we ran the generator every night for 3 to 4 hours to get back to 97% – 100% SOC. By morning we were usually at 70% to 73% SOC. In the morning, we would run the generator again to build up to 85% or so and that would take another 3 hours. Then we conserved energy by only running refrigeration, fans, our instruments etc. Our small solar array would get us close to 97% – 100% SOC by 3:30, but by 8:00 pm we’d be back in the high-70’s to low-80’s so the generator would be needed again to recharge the batteries to make it until morning. Overnight, we went back into “essentials only mode”. We did it every day. Now, on most days, we keep our SOC from 75% – 95% with solar alone. We only run the generator when we make water or fill our scuba tanks. We can make water without running the generator, but we like to run it 2 – 3 times per week so that it stays in good operating condition. We used to average between 50 to 55 hours per week on the generator, now it’s 10 – 12 hours per week. We’ve had lots of rain lately. If it’s rainy for 2 full days, we get down to 50% – 55% SOC. Our lowest SOC after almost 2 ½ days of rain was 52%. It’s incredible the amount of power we now have compared to our old system!

Cruisers spend lots of time, effort, and money trying to be efficient power managers. On a boat underway, at anchor, or on a mooring, one must be totally self-sufficient in power production and power management. Most cruisers can tell you how many amps everything on their boat pulls, from a single LED light to their most power-hungry appliance. Cruisers know whether the coffee pot and microwave can run at the same time, and if the water maker and washing machine can operate simultaneously. “Yes, we can make water, wash clothes, charge one phone, and turn on two lights, but don’t turn on the radio too, we’ll throw a breaker!” Because a sailboat has limited power available and a limited ability to produce power, it takes coordination to manage things efficiently. We think our new system will be well worth the expense and effort. It should provide us with greater freedom and comfort onboard.

A final thought on power conversions: Although many sailors have the expertise, electrical, and mechanical ability to complete a conversion successfully, we could never do it and have a safe boat. People ask, “What’s your greatest fear living and traveling on a sailboat?” The answer is easy – a fire onboard. We were far out of our element as we undertook this upgrade to Ocean Song. We’ve heard many stories of DIY lithium conversions that never worked quite right and often become electrical hazards. A big shout out to Guy Bazzani for recommending Kenrick and Aaron who’ve done work for him. Like I said we mostly copy what Guy and Carole do. Kenrick did a fabulous job on the metal fabrication and solar installation and Aaron brought everything together and made it work! Aaron worked as hard as anyone who has ever done any type of work on Ocean Song. He spent more than 2 weeks onboard working in extreme heat and humidity. Great Job!

A final thought on power conversions: Although many sailors have the expertise, electrical, and mechanical ability to complete a conversion successfully, we could never do it and have a safe boat. People ask, “What’s your greatest fear living and traveling on a sailboat?” The answer is easy – a fire onboard. We were far out of our element as we undertook this upgrade to Ocean Song. We’ve heard many stories of DIY lithium conversions that never worked quite right and often become electrical hazards. A big shout out to Guy Bazzani for recommending Kenrick and Aaron who’ve done work for him. Like I said we mostly copy what Guy and Carole do. Kenrick did a fabulous job on the metal fabrication and solar installation and Aaron brought everything together and made it work! Aaron worked as hard as anyone who has ever done any type of work on Ocean Song. He spent more than 2 weeks onboard working in extreme heat and humidity. Great Job!

*1 Our old inverter was a 2,500-watt unit. We traded our old inverter, and some miscellaneous electrical parts Aaron had removed to Dominic, who owns the mooring we were on, in exchange for a month’s mooring fee.

*2 We’ve noticed there is a difference in solar output when our dinghy is on the davits under the solar arch. The dinghy blocks some of the sunlight that reflects off the water to the underside of the solar panels.

Leave a Reply